Given today’s environmental challenges and the impact of construction, materials selection at the outset of an architectural project is a critical decision.

In our effort to promote local building practices, reduce environmental impact, and favour short supply chains, our team works alongside all project stakeholders to facilitate the use of raw earth materials. We are involved throughout architectural projects, from planning to project completion, as well as in setting up material production chains.

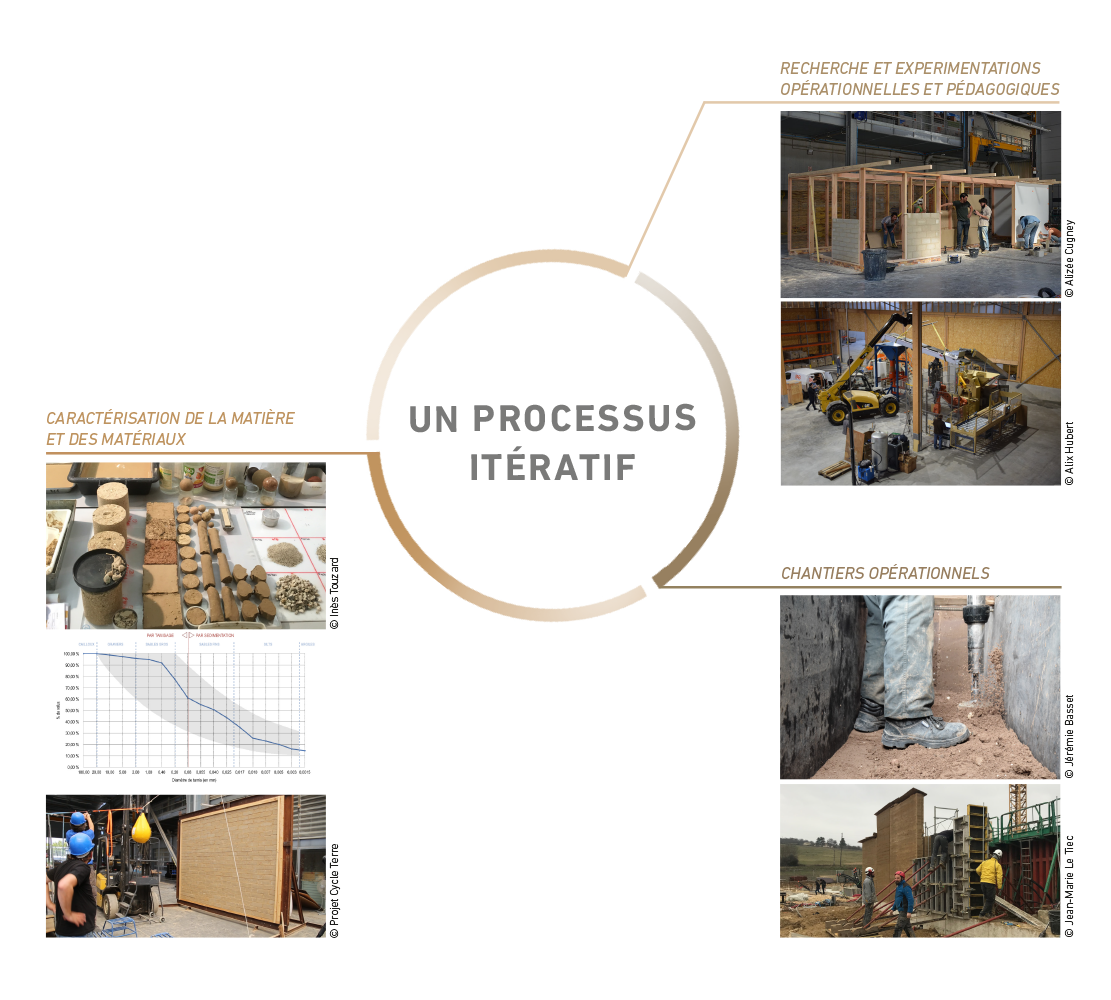

The Materials unit focuses its activities on 3 main areas

- 1

Understanding matter and materials

- 2

Construction systems, production methods and innovation

- 3

Evolution of the regulatory framework

Skills and services

The Materials Unit provides expertise in the following areas:

Support for project management and project owners

Support for construction companies

Structuring raw earth material supply chains for construction

Technical and regulatory validation

Methodology

The Materials Unit serves as a bridge between materials and architecture. We consider the full scope of the construction process—from assessing the potential of a territory to the successive stages of material production, structural design, and building implementation. Each project becomes an opportunity to reinforce the building culture of a territory and empower its stakeholders.

Define a method for identifying and leveraging local resources in housing production

- Extraction and production of building materials in regional development

- Enhancing the value of local materials and adapting their associated know-how to contemporary construction.

- Setting up production chains: basic conditions and key stages.

Caractériser les techniques de construction en terre et d’autres matériaux non industriels

- Identify construction techniques with high utilization potential and prepare and support the process of characterizing them (in conjunction with STI laboratories).

- Exploration and characterization of simplified (field) test procedures for earth construction

- Assistance in drawing up standard documents, from Atex level (BTCs, Pisé, etc.) to higher levels of standardization.

Exploring possible uses for new urban resources under construction

- Assessing construction uses for excavated soil

- Reuse of building materials/components: potential and limits